Tune-It: Optimizing Wire Reconfiguration for Sculpture Manufacturing

ACM SIGGRAPH Asia 2024 (conference track)

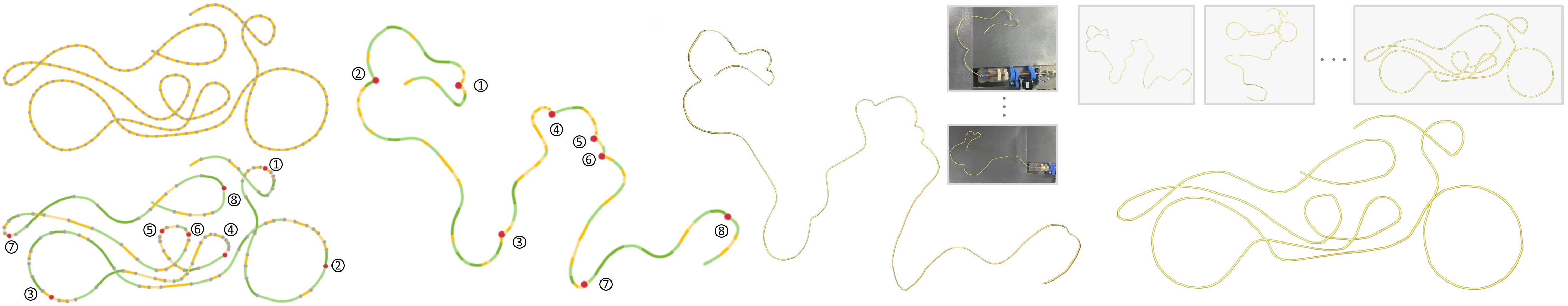

We introduce a novel computational framework for wire sculpture fabrication that seamlessly integrates the strengths of wire-bending machines and human craftsmanship. The input wire (top of (a)) is fitted into a segment-bendable wire (bottom of (a)) with bending fabricable line segments and circular segments (indicated in different colors), considering the manufacturing constraints of wire-bending machine. For collision-free wire bending, we generate a tuned wire in which tuned points are indicated with red dots (b). The manufacturing result after the machine-bending stage with our DIY bending machine (c). The final result after the human-bending stage by a non-skilled participant (d).

Abstract

Wire sculptures are important in both industrial applications and daily life. We introduce a novel fabrication strategy for wire sculptures with complex geometries by tuning the target shape to a collision-free shape for the wire-bending machine and then bending it back to the target by a human. The key challenge lies in tuning the least number of bending points, which is formulated as an "Optimizing Wire Reconfiguration" problem. We first fit the input target wire with consecutive line segments and circular segments to ensure the bending manufacturing constraints for each segment, then generate tuned wire through a bilevel optimization. This involves selecting the bending points at the upper level with a beam search strategy and determining the specifically tuned angles at the lower level. We perform a thorough physical evaluation using a DIY wire-bending machine. The results show the effectiveness of our proposed approach in realizing a wide range of intricate and complex wire sculptures.

Video

Algorithm overview

In this paper, we present a fully automatic computational framework to make problem OWR tractable which enables us to generate a collision-free tuned wire, with as few uned points as possible. First, fit the input wire into a set of fabricable bending segments, such as 3D line segments and circular segments, so that the fitted line segments and circular segments meet the bending manufacturing constraints. Second, generate tuned wire through bilevel optimization, where the upper-level optimization focuses on selecting the bending points to be tuned, while the lower-level optimization aims at determining the tuned angles with the consideration of eliminating all collisions. Moreover, we explore a weighted beam search strategy to trade off search efficiency and solution quality. Finally, we validated our algorithm by conducting experiments on 3D models and fabricating a set of 2D models using a DIY bending machine.

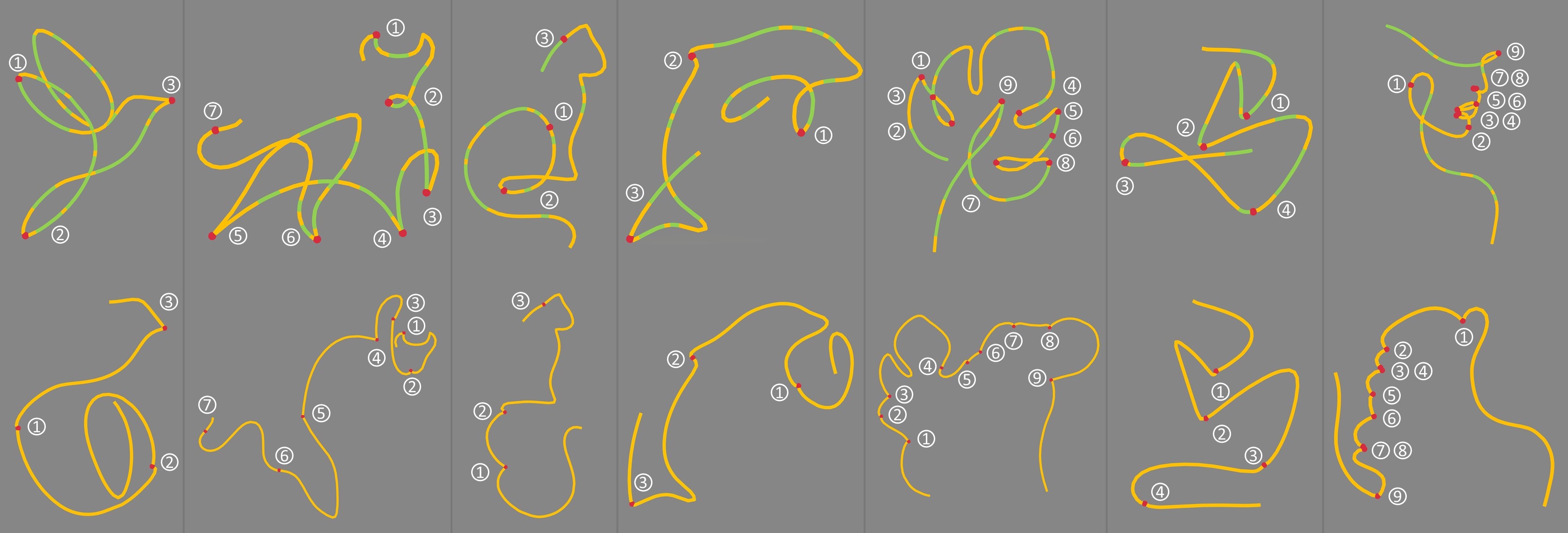

More tuned results

Results gallery generated by our algorithm. The models are arranged in the order of Bird, Bull, Cat, Dolphin, Leaf, Ma (i.e. the simplified Chinese character of horse), Woman. We show both the fitting result (line segment: Green, circular segment: Yellow) and the deformed wire after bending the tuned points.

Thirteen results of 2D wire art examples. The models are arranged in the order of Man, Runner, Hat woman, Side face woman, Writing, Game player, Tree, Car, Guitar, Flower, Cake, World map, Rabbit. We show both the fitting result (line segment: Green, circular segment: Yellow) and the tuned wire.

Results of multi-view wire arts generated by Tojo2024Wireart. Top-left: View 1. Top-right: View 2. Bottom: tuned wire. The models are arranged in the order of Cat-dog, Einstein-Newton, Elephant-giraffe, Bull-horse, Tree-flower.

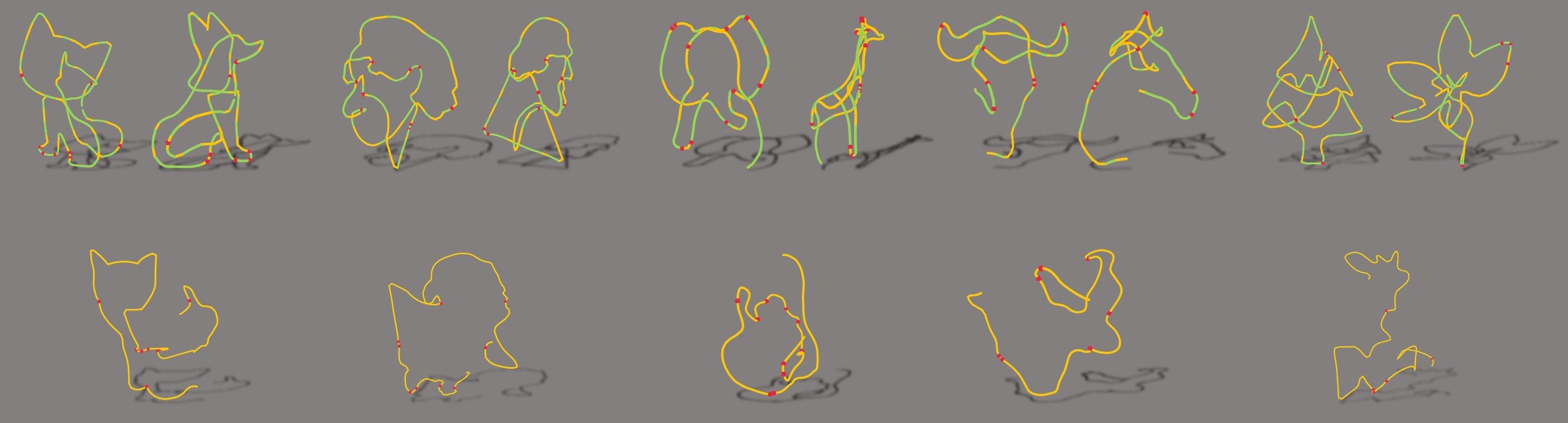

Fabrication results

Results gallery generated by our Machine-And-Then-Human-Bending strategy. The models are arranged in the order of Bird, Woman, Cat, Ma (i.e. the simplified Chinese character of horse), Leaf, Dolphin, Bull. Each set of images includes photos of the machine bending completed (golden) and the human bending completed (golden). The small image (white) in the corner of each photo is the theoretical rendering of that image. These photos use the maximum filter with parameter 2.8 for visualization, but the process does not change any shape.

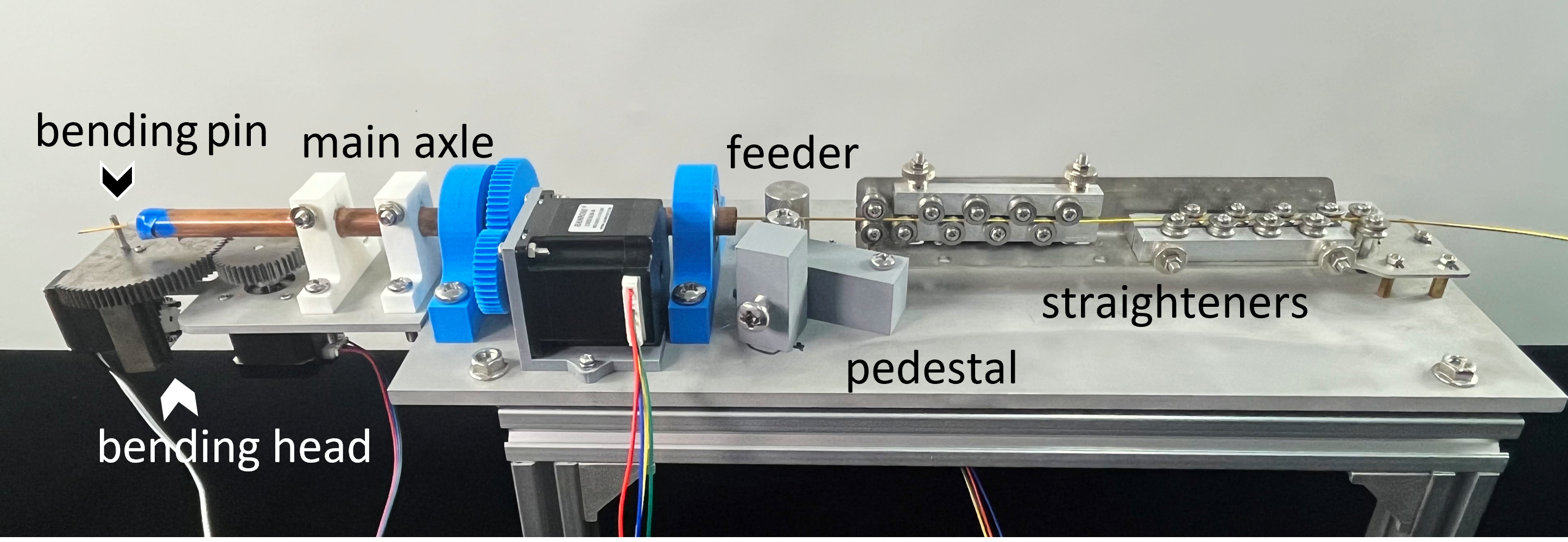

Our wire bending machine

Our DIY wire bending machine, based on tutorial, consists of straighteners, a wire feeder, a bending head with bending pin, and pedestal. The rotation center of the bending pin is aligned with the wire outlet. The DuPont wires in the picture connect the motors and drivers.

Downloads