Connected Fermat Spirals for Layered Fabrication

SIGGRAPH 2016

1Shandong University 2TTI Chicago 3Purdue University 4USC 5Simon Fraser Universtiy 6Tel-Aviv University

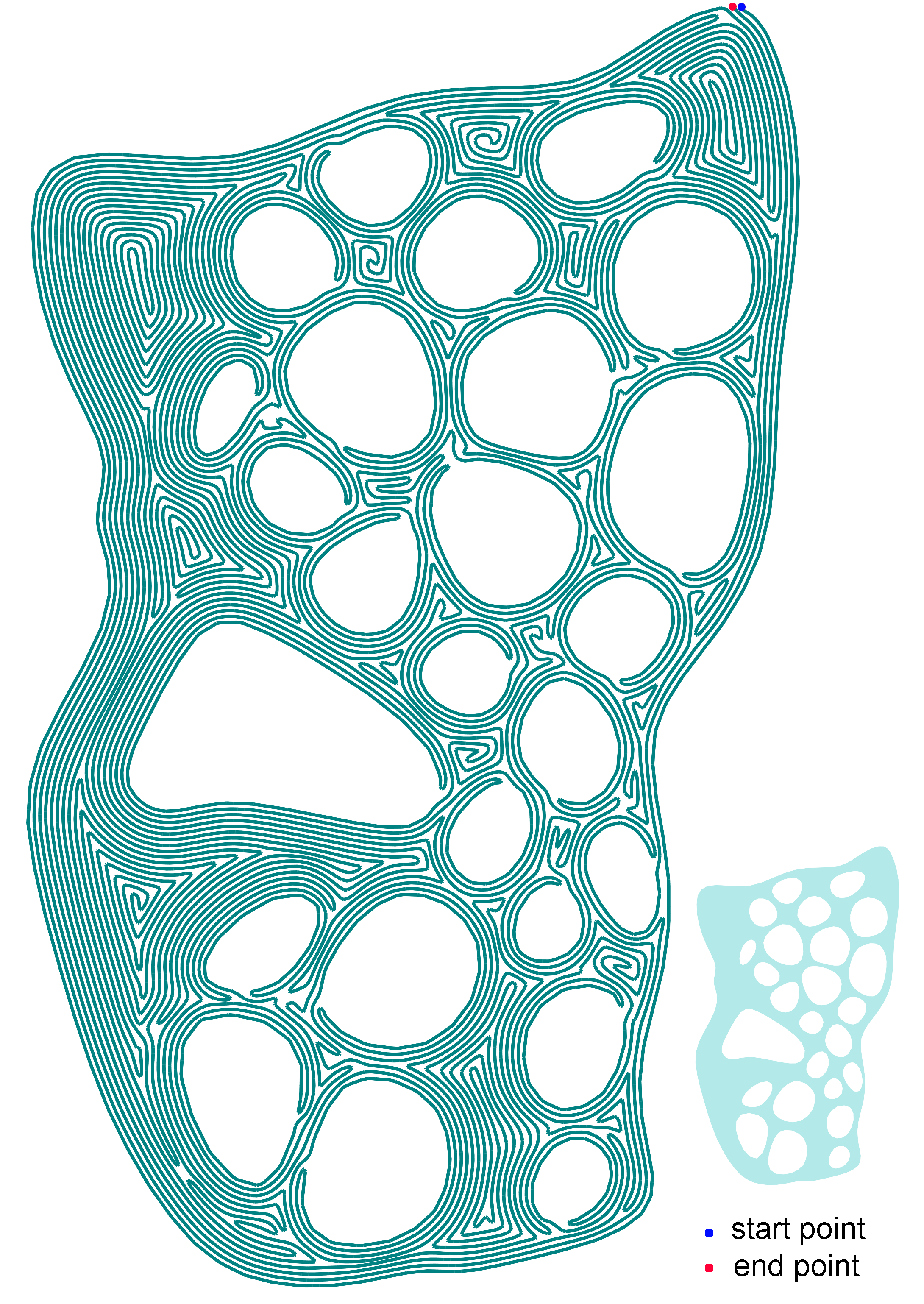

A new kind of “space-filling” curves called connected Fermat spirals. Unlike classical space-filling curves which wind and bend, the new curve is composed mostly of long, low-curvature paths, making it desirable as a tool path fill patten for layered fabrication. The tool path shown is continuous with start and end points marked; the input 2D layer shape is displayed on the side.

Abstract

We develop a new kind of "space-filling" curves, connected Fermat spirals, and show their advantages as a tool path fill pattern for layered fabrication. Unlike classical space-filling curves such as the Peano or Hilbert curves, which constantly wind and bind to preserve locality, connected Fermat spirals are formed mostly by long, low-curvature paths. This geometric property, along with continuity, greatly influences the quality and efficiency of layered fabrication. Given a connected 2D region, we first decompose it into a set of sub-regions, each of which can be filled with a single continuous Fermat spiral. We show that it is always possible to start and end a Fermat spiral fill at approximately the same location on the outer boundary of the filled region. This special property allows the Fermat spiral fills to be joined systematically along a graph traversal of the decomposed sub-regions. The result is a globally continuous curve. We demonstrate that printing 2D layers following tool paths as connected Fermat spirals leads to efficient and quality fabrication, compared to conventional fill patterns.

Video

Simulated and captured physical printing process

Fastforward

Two+ Minute Papers edited by Károly Zsolnai-Fehér

More results

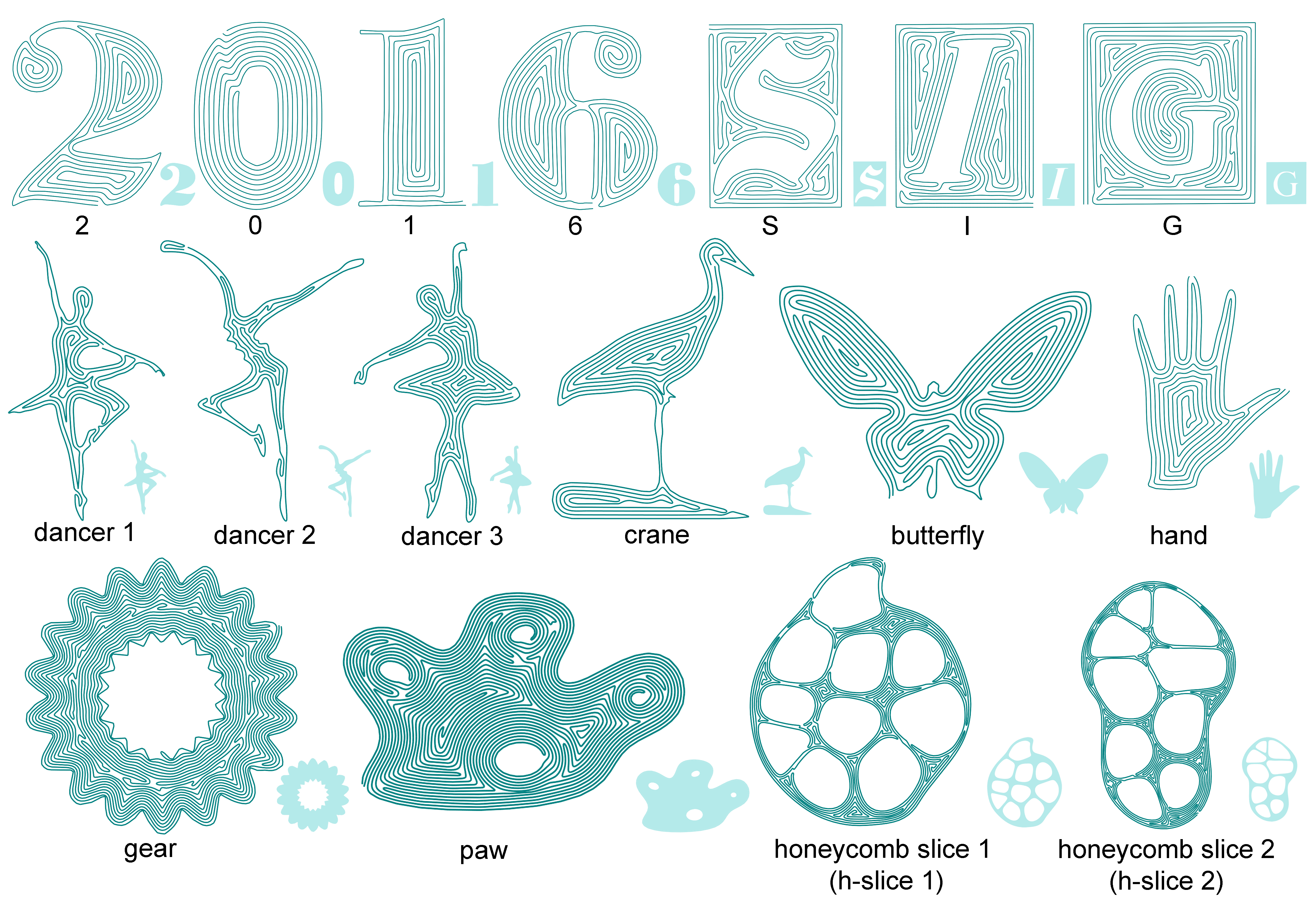

A gallery of continuous CFS tool paths generated by our algorithm. Shown as insets, the input shapes, both synthetic and from slices of fabricated 3D objects (see the honeycomb slices in last row as well as in the teaser figure), exhibit varying degrees of complexity in terms of convexity/concavity of boundaries and hollowness. The top two rows show lower-resolution results for ease of visualization. The bottom row shows higher-resolution results, which are closer to that of real fabrication and also demonstrate robustness of our method.

Downloads

Acknowledgement

We would first like to thank all the reviewers for their valuable comments and suggestions. The development of our problem formulation was critically influenced by discussions with Dan Halperin, to whom we are grateful. Thanks also go to Yang (Sherry) Liu (illustration), Shenqi Liu and Hao Xu (3D printing), Sha (Ada) He (video), and the rest of the SDU lab-mates for their tremendous help on production. This work is supported in part by grants from National 973 Program (2015CB352501), NSFC (61232011, 61202147, 61332015, 61572291), NSERC Canada (No. 611370), Israeli Science Foundation (No. 1790/12), U.S.-Israel Bi-National Science Foundation (No. 2012376), and gift awards from Adobe and Intel.

BibTex

@article {zhao_sig16,

author = {Haisen Zhao and Fanglin Gu and Qi-Xing Huang and Jorge Garcia and Yong Chen and Changhe Tu

and Bedrich Benes and Hao Zhang and Daniel Cohen-Or and Baoquan Chen},

title = {Connected Fermat Spirals for Layered Fabrication},

journal = {ACM Transactions on Graphics (Special Issue of SIGGRAPH)},

volume = {35},

number = {4},

pages = {Article No. 100},

year = {2016}

}